Product short description:

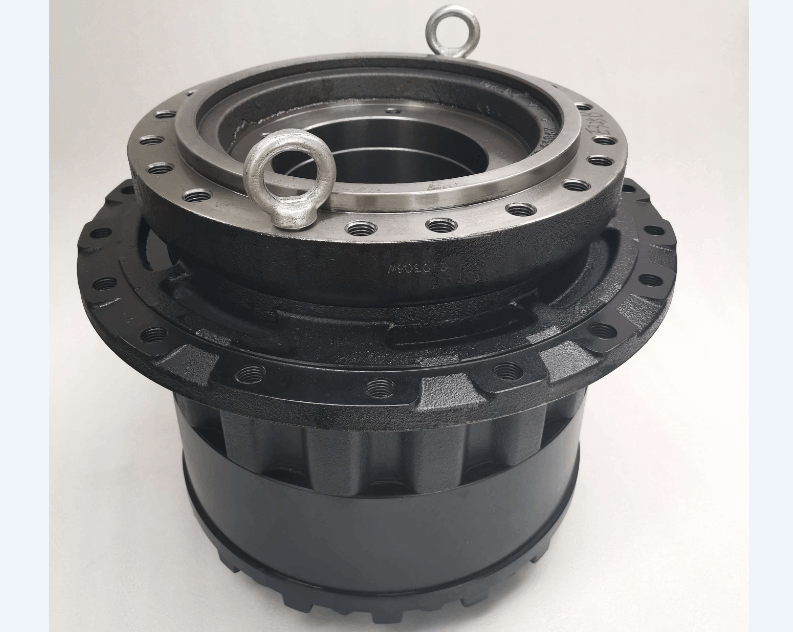

Particularly important elements of the whole undercarriage system are also tracked and top rollers.

At present,manuuacturers employ rollers that are pre-filled with oil for their entire life.Maximum resistance to abrasion of the undercarriage elements mentioned if obtained due to the use of adequate castings,precision machine treatment and inductive quenching.

Additionally,very good parameters are obtained due to tempering,which increases durability and extends life of rollers,ensuring their even wear.

Principally,rollers used in excavators and in bulldozers differ in their external design.Besides ,despite their internal design being baically identical,bulldozer rollers are built more massively,guaranteeing extended life.

| Product name | Aftermarketing carrier roller |

| Material | 50Mn,40Mnb |

| Technique | Forging&Casting |

| Surface hardness | HRC48-56,Deepth 4mm-10mm |

| Color | Black/Yellow |

| Finish | Smooth |

| Warranty time | 2000 Hours |

| Package | Fumigate wooden pallet packing |

| Delivery time | Within 15-20 days after contract established |

| Payment term | T/T 30% in deposit,balance on the receipt of copy of B/L |

|

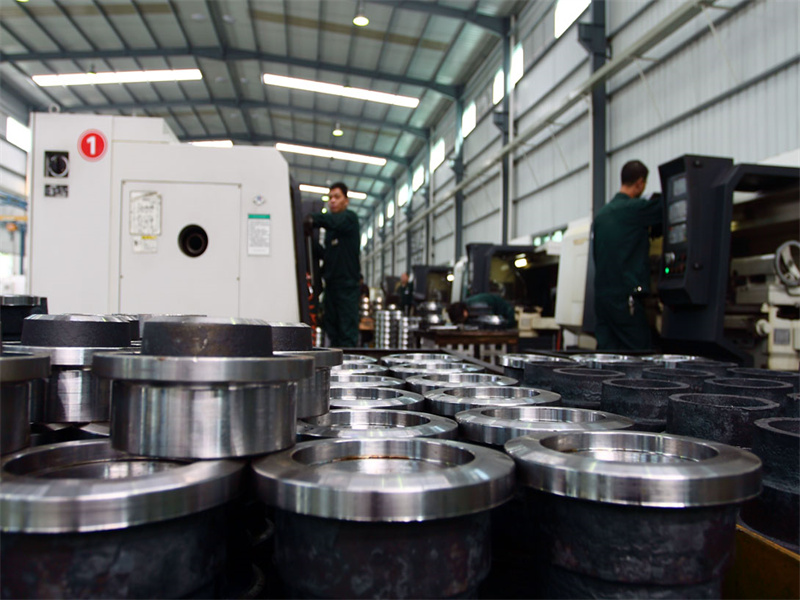

Factory show

|

|

|

|

|

|

Shipping&Packing

|

|

FAQ

Q1: I want to buy your products, how can I pay?

A:You can pay via T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow.

Q2:How can you guarantee the quality?

A:Warranty period, if you meet with quality problem, we promise to replace goods or return your funds.

Q3: Can we buy 1 pcs of each item for quality testing?

A:You can buy a sample to do quality inspection.

Q4:What can you buy from us?

Excavator parts,Bulldozer parts,Excavator and bulldozer undercarriage parts.