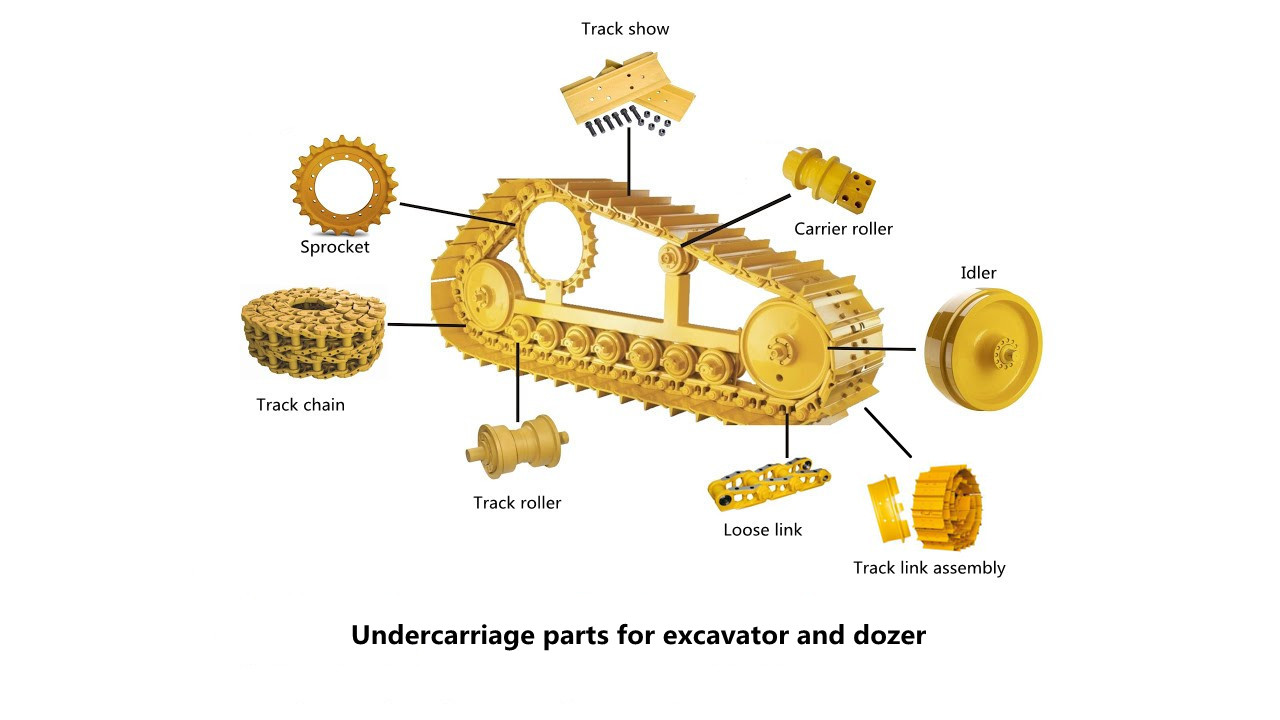

TRACK ROLLER

The purpose of track roller is to transfer the weight of the chain to the ground and roll on the tracks.In order to prevent derailment,track roller should also prevent the track from moving horizontally relative to it.

Track roller often works in mud,water and sand,and bears strong impact,the working conditions are extremely bad,the rim is easy to wear.

The requirements of the support wheel are:wear resistant rim,reliable bearing seal,small rolling resistance and so on.

CARRIER ROLLER

The functon of carrier roller is to keep the chain track in a straight line.If the carrier roller is damaged,the track chain track cannot keep the straight line.

Carrier roller is a one-time injection of lubricating oil,if there is oil leakage can only be replaced,in the work should try to aviod supporting wheel long time immersion in muddy water.

SPROCKET

The sprocket is a transfer force,can change the speed of rotation,can change the direction of rotation.

IDLER

The excavator front idler is used to guide the track to turn correctly to prevent it of running of track and deviating.Most excavators also play the role of a heavy wheel.

In this way,the contact area between track and ground can be increased and the specific grounding pressure can be reduced.

The wheel surface of the guide wheel is made of smooth surface,and there is baffle ring in the middle as a guide,and the torus on both sides supports the rail chain.

TRACK CHAIN

The tightness of excavator track is is like the size of shoes worn by pepole,which must be adjuster to the best state to move forward.In the working operation of excavator.

It often causes the change of crawler's tightness,and the tightness of crawler also determines the wear degree of the chain to its contact accessories.

TRACK CHAIN ASSEMBLY

The track chain assembly is composed of two parts:the track shoe and track chain,and the two parts are joined together by bolts and buts.

Sign up to our newsletter for the construction machinery