What are the parts of a bulldozer undercarriage?

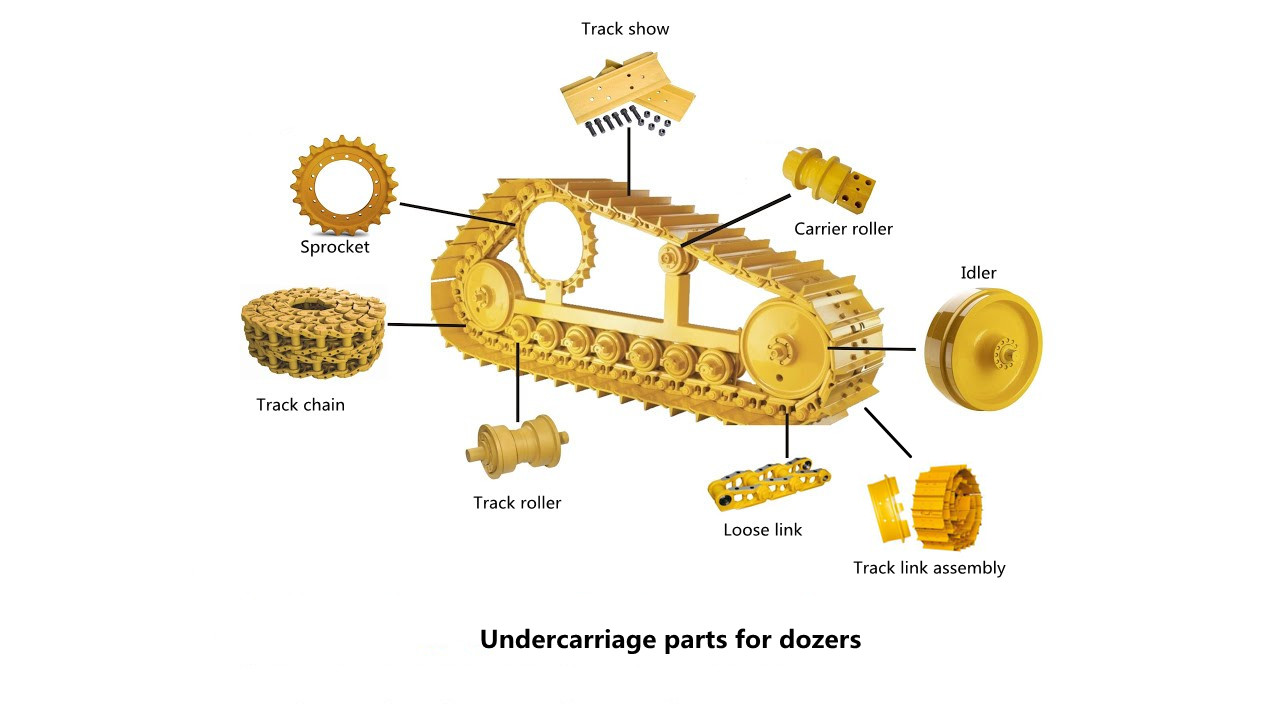

A tracked bulldozer’s undercarriage allows the machine to move forwards and backwards simply and efficiently and that movement takes a number of different parts working together to happen. Some of the most important parts in the dozer undercarriage are:

In construction equipment, tracks can either be metal or rubber. Metal tracks are created by linking together a number of track shoes using flexible connections that allow the track to rotate around points at the ends of the tracks. Grousers (flared or protruding metal cleats) integrated into the trackshoes provide metal tracks with added traction in low friction environments like mud or snow.

2.Idler

Idler at the end of the track will be used to keep the track on its path and, in combination with the track adjuster, set how tight or loose the track is.

3.Recoil spring&track adjuster

Recoil springs are connected to the idler (though the yoke) and protect the track from impacts. These springs work with a track adjuster to maintain a specified amount of tension in the track and to allow that tension to be adjusted depending on certain working conditions.

The final drive on a dozer undercarriage is the part responsible for turning the track and propelling the machine forwards and backwards. By converting hydraulic energy into mechanical power the final drive turns the sprocket and in turn, rotates the track. Inside of the final drive, planetary gears transform high speed input into low speed, high torque output and its this high torque power that gives the dozer its incredible pushing power.

5.Sprocket

The sprocket on a bulldozer is a large cogwheel (either one singular part or several disparate segments) with teeth that interact with the track’s pins and bushings and turn the track. As the final drive turns the sprocket, the teeth of the sprocket create wells in which the pins engage and are carried forward or backward (similar to how a bicycle chain and sprocket work).Because of the constant friction under which the sprocket’s teeth operate, the bulldozer sprocket has a finite lifespan and must be replaced after a certain time.

Carrier roller and track rollers in a dozer’s undercarriage keep the track aligned and properly taut and shaped. Bottom rollers carry the weight of the bulldozer and maintain clearance off the ground, while top rollers prevent the track from sagging. The work of all rollers on the machine can be impacted as the tracks become clogged with dirt and mud and the tension on the track is increased.

Sign up to our newsletter for the construction machinery