Excavators are a classic piece of construction equipment with an eye-catching silhouette. The boom rears above the other machines on the construction site, and the tracks are ridiculously filled with muck while the dump trucks wait in line like a pack of ants. Wherever it works, the excavator is the king of the job site. In this article, we’ll be discussing in-depth the different parts of the excavator.

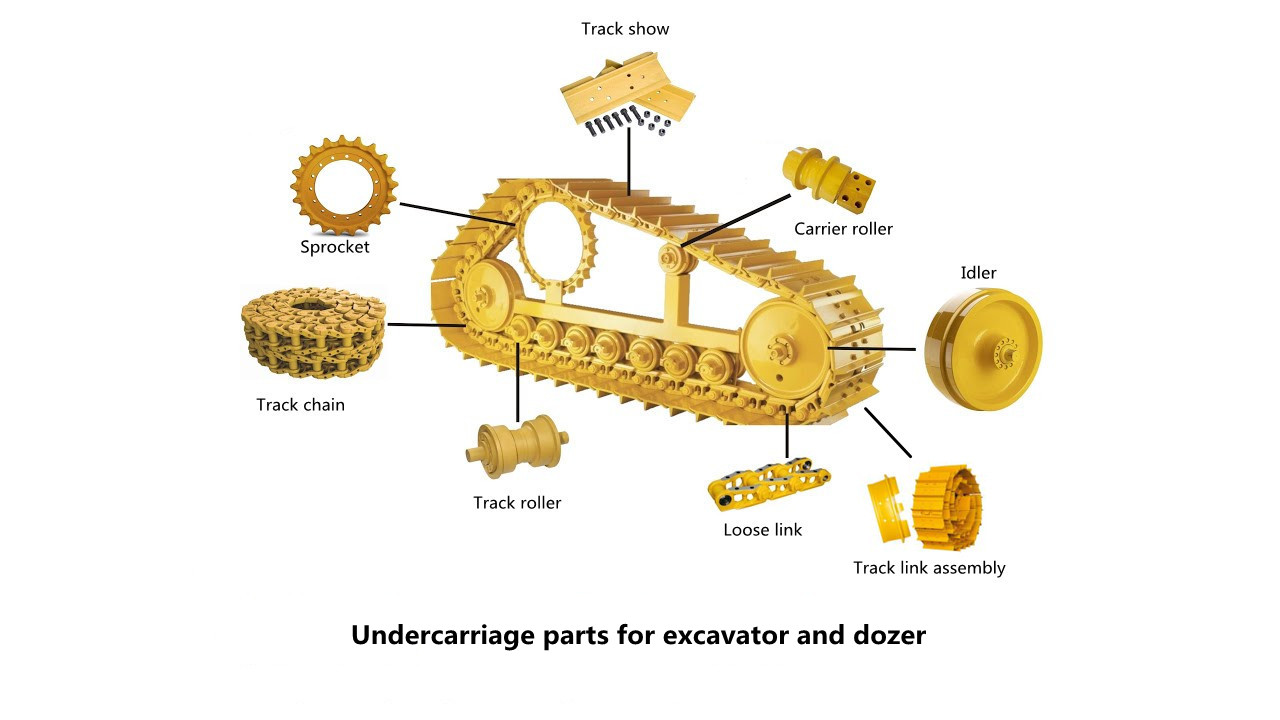

The Undercarriage

An excavator’s undercarriage includes the tracks, track frame, hydraulic motor, and gears. Wheeled excavators would use wheels and an axle instead of a track and track frame, but the fundamentals would remain.

1. Tracks

Tracks line the track frame and are what enable the excavator’s ability to move over uneven surfaces. Excavator tracks can be equipped with either metal or rubber, depending on the working surface.

2. Track Frame

The Track frame is the rectangular steel frame that comprises the main body of the undercarriage. It is connected to the Excavator house by a center pin. The track frame contains the slew ring, swing gear, swing bearing, and hydraulic swivel that allow the excavator to perform 360-degree turns.

3. Final Drives

The Drive powers the tracks and enables the independent movement of each track to perform left, and right turns.

4. Blade

Dozer blades are an optional addition to the undercarriage and function to clear loose ground material for smoother excavator motion.

House

The House is most known as the excavator’s cab. Some people consider the cab a fully independent component of an excavator, while others include it with the House. Most modern excavators come equipped with plenty of operator-convenient features like AM/FM radio connection and seat heaters, just like this 2015 Hitachi ZX210LC-5B Hydraulic Excavator.

1. Operator Cab

The operator cab houses the operator and is responsible for sheltering the operator and the controls from any dangerous debris or projectiles. The window structure provides a 360-view to the operator. Most excavators like this 2013 John Deere 250G Hydraulic Excavator can be equipped with Cab Guard for even greater protection.

2. Counterweight

Counterweights are incorporated in excavators to balance out the heavy digging arm that might otherwise tip the excavator over. ]

3. Engine

Diesel engines are most commonly used to power excavators mainly due to their higher horsepower capacity than petrol. The excavator engine powers the three hydraulic pumps, which supply oil to the various moving parts and minimizes operator fatigue by autopiloting the spool valves.

4. Fuel and Hydraulic Fluid Tanks

Excavator fuel tanks are usually housed in the rear part close to the engine, making it easy to refuel.

Arm / Boom

Whether you look at the boom or arm as one part and attachments as another, one thing’s for sure, and it’s that they rely on each other. This is why the excavator’s arm is often seen as the third part of the machine, and they are not separated.

1. Boom

The boom is on the upper portion of the digging arm and is attached in front of the housing. The boom is responsible for the up and down movement of the arm.

2. Stick

Otherwise known as the dipper arm, the stick is responsible for the digging movement of the excavator. A hinged joint attaches it to the end of the boom.

3. Bucket

The bucket is attached to the bottom end of the stick. It is pulled by a cylinder on the outside of the stick to haul material.

4. Attachments

Attachments are optional tools that can replace the bucket. This can include augers, log splitters, earth drills, compactors, and many others. The 2008 John Deere 160C-LC Hydraulic Excavator, in particular, is compatible with a screw pile attachment which is excellent for drilling projects.

Sign up to our newsletter for the construction machinery